.................................................................................................................................................................................................................................................................................................................................

TECHNICAL INFORMATION

Click on desired heading to jump to selection

6.0 CASTOR TERMINOLOGY / DEFINITIONS

10.0 WHEEL TERMINOLOGY / DEFINITIONS

All dimensions are in mm and all loadings are in kg unless stated.

Working conditions vary enormously with regard to both the type of floor and the

severity of the application. Load ratings are based on intermittent use on normal truck

or trolley applications. Special conditions may apply under any of the following

applications or hazards:

- Uneven floor surface.

- Ramps, cracks, gullies, door guide rails.

- Track or turntable use.

- Power towing or driven wheels and rollers.

- Any application other than manually propelled truck and trolley use.

It may be appropriate, in certain circumstances, to select a castor or wheel with a load

capacity much greater than appears necessary, please ask our technical sales team

for assistance in product selection.

All moving parts are liberally treated with a high quality grease. This forms a protective

layer which minimises wear by metal to metal contact. Many swivel castors are fitted

with swivel head seals helping to reduce maintenance to a minimum. Where

lubrication is necessary, this should be carried out using a pressure oil gun, taking

care to ensure that the lubricant reaches the king pin head on single ball race castors.

In addition, heavier duty castors and wheels are often fitted with grease nipples and/or

dimpled and drilled axle bolts for replenishment purposes under arduous working

conditions.

Nylon wheel bushes are virtually self-lubricating but will benefit from occasional

lubrication, particularly in very dusty conditions.

A general purpose lithium based grease is used in most castors with a normal

operating temperature range of -30c to +130c.

3.1 Low temperatures

In low temperatures, the consistency of the grease increases up to a point where the

swivel and rolling performance is reduced. For low temperature applications it is

recommended that a double ball race castor is used and fitted with low temperature

grease. Please ask for details.

3.2 High temperatures

In high temperature applications the grease will operate satisfactorily but will need

regular replenishment. This particularly applies in forced draught ovens where the oil

component of grease can be volatilised causing carburisation. Castors fitted with high

temperature wheels and grease are detailed in the Special Application Castors

catalogue. High temperature wheels are listed in the Special Application Wheels

catalogue. Please request a copy.

In general, castors can be sub-divided into two main types:

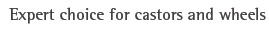

4.1 Pressed steel

Pressed steel castors incorporate single or double ball bearing swivel race way

construction. The balls run in tracks formed in the fork and top plate pressings which

are secured together by a heavily riveted steel king pin.

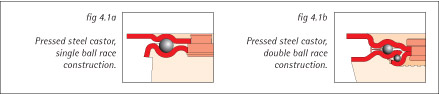

4.2 Fabricated steel

Usually consisting of precision machined heavy steel forgings housing combinations

of tapered roller or ball bearing races. The fork legs are usually securely welded to the

swivel head forging giving an extremely strong construction suitable for heavy loads.

Castor applications can be divided into two main categories:

5.1 Castors for use on trucks, trolleys, trailers etc. and used as a means of

transportation (i.e. loaded with goods and regularly moved from one place to another).

It is essential that castors should have the lowest tractive resistance and be able to

swivel freely so that the trolley can be manoeuvred without too much effort. To achieve

this, wheels should be at least 100mm in diameter and preferably 150mm or more,

regardless of the rated load capacity.

5.2 Castors fitted to equipment enabling it to be delivered to the place of use allowing

occasional movement over short distances. Smaller castors may well be suitable and

are often used at their full capacity.

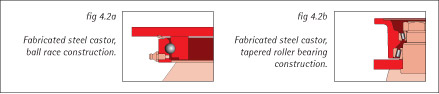

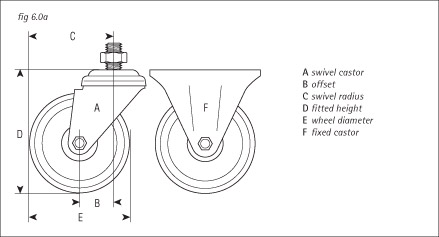

6.0 CASTOR TERMINOLOGY / DEFINITIONS (fig 6.0)

A castor consists of a wheel fitted into swivelling or non-swivelling forks. The wheel is

usually retained between the castor forks using a simple axle set. Some castor

components are described using differing terms by various manufacturers.

6.1 Swivel castors (fig 6.0a)

A housing containing a wheel which is free to swivel without restriction about the

vertical axis of the swivel bearing with the castor wheel axle offset.

6.2 Fixed castors (fig 6.0a)

A housing containing a wheel which is not to swivel about its vertical axis.

6.3 Wheels

A revolving centre rotating freely on an axle of which the external part (in contact with

the ground) can be constituted by the material of the wheel itself or by a tyre of various

other materials.

6.4 Offset (fig 6.0a)

The horizontal distance between the centre of the wheel axle and the vertical axis of

the swivel bearing. Also known as the trail.

6.5 Swivel radius (fig 6.0a)

Usually the horizontal distance between the outside edge of the wheel and the vertical

axis of the swivel bearing. This can be increased by fitment a brake whose operating

pedal may protrude beyond the outside edge of the wheel.

6.6 Fitted height (fig 6.0a)

The height by which a piece of equipment will be raised by fitting a castor. In the case

of certain fixing types, not necessarily the overall height of the castor (see diagram).

6.7 Wheel diameter (fig 6.0a)

The overall diameter of the wheel (including tyre, if fitted).

6.8 Tractive resistance

The effort required to move a piece of equipment fitted with castors or wheels. It is

vitally important to be able to predict the amount of effort required to either push a truck

in a straight line or to manoeuvre it in tight spaces. When this information is known it

should be possible to calculate the number of personnel required to move and control

the truck in normal workshop conditions. Tractive resistance is usually expressed as a

percentage of the total load to be carried and an approximate guide is as follows:

Hard tread wheels Less than 1%

Polyurethane tyred wheels Approximately 2%

Rubber tyred wheels Approximately 3.5%

This guide is based upon 200mm diameter roller bearing wheels. It should be

remembered that a typical human being is capable of maintaining a horizontal force of

approximately 12kgf increasing to about 18kgf from a standing start. Polyurethane

wheels if left standing under full load for a substantial length of time could require at

least twice the force to initiate movement, its tractive resistance will increase

momentarily up to about seven times the figure given above.

The means by which a castor is fitted to the equipment. The main types are as follows:

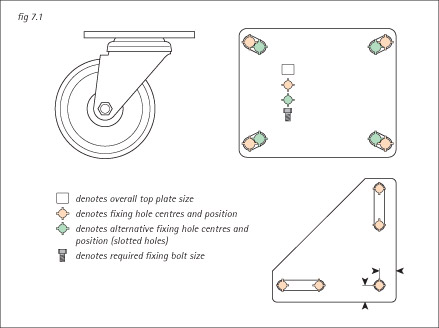

7.1 Plate fixing (fig 7.1)

Normally a rectangular plate with four fixing holes (exceptions include 3 hole

triangular plate and 2 hole rectangular plate. ISO 2184 sets out a range of

standardised fixing hole centres as follows:

Class 2: 80mm x 60mm

Class 3: 105mm x 80mm

Class 4: 140mm x 105mm

While most products conform to these standards, in some cases fixing holes are

elongated to allow for fitting at alternative hole centres such as those to the DIN

standard or popular North American sizes. Top plate diagrams shown in the catalogue

clearly illustrate hole sizes and positions. Customers are advised to fit to the ISO

standards wherever possible and avoid placing bolt anywhere other than at the end of

slotted holes.

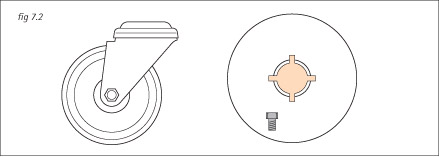

7.2 Bolt hole / single bolt fixing (fig 7.2)

A single hole positioned in the centre of a circular top plate, suitable for fitting a loose

bolt from beneath the swivel head or fixing to a stud attached to the equipment.

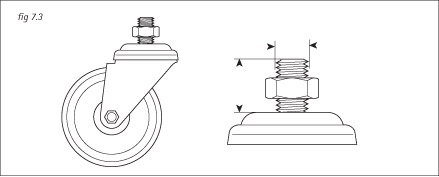

7.3 Threaded stem fixing (fig 7.3)

A fixed stud attached to the castor swivel head. Usually supplied with a loose nut.

Check for availability.

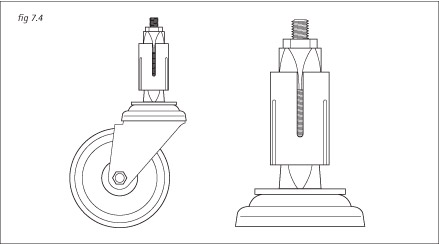

7.4 Expanding adaptor (fig 7.4)

For fixing into square or round tube. Secured by tightening head of hexagon or allen

headed bolt concealed beneath swivel head of castor.

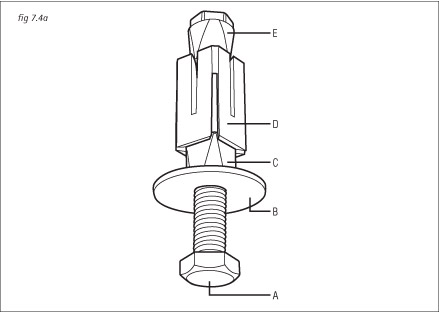

Fitting an expander (fig 7.4a):

i. Assemble the bolt (A) to the castor so that the bolt head is inside the swivel head.

i.e. Thread protruding from top of castor.

ii. Slide washer (B) over bolt.

iii. Slide bottom cone with plain hole (C) over bolt so that the smaller square end is

facing up.

iv. Slide sleeve (D) over the bolt. The sleeve is the same at each end so orientation is

not required.

v. Align flats on bottom cone with the flats on inside of sleeve.

vi. Screw top cone with threaded hole (E) down bolt so that the small square end

aligns with flats on inside of sleeve. When correctly fitted, sleeve and cones rotate

together and are in line but loose and ready for fixing.

To fix the castor with expander assembly, offer up to tube and push expander

assembly fully home. i.e. castor is in contact with base of tube. Tighten the bolt to a

maximum of 10Nm for M12 bolt or 8Nm for M10 bolts and ensure the castor is securely

fitted.

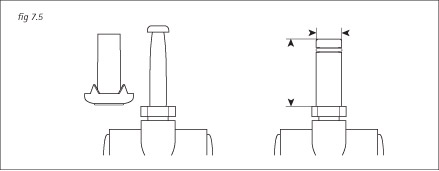

7.5 Furniture fixings (fig 7.5)

Peg and socket to suit drilled hole in wood or push-fit circlip stem for hole in metal

e.g. chair base. Commonly available with ball type or twin wheel furniture castors.

Castors are available fitted with a wide variety of adaptations to meet the needs

oindividual applications:

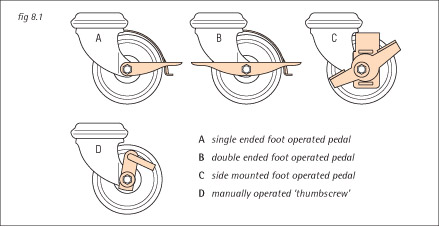

8.1 Wheel brake (fig 8.1)

A single or double ended foot operated pedal brings a metal pad into contact with the

tread of the wheel which acts as a parking brake. Alternatively, a manually operated

cranked pin or ëthumbscrewí can be tightened against the wheel centre to achieve a

similar effect.

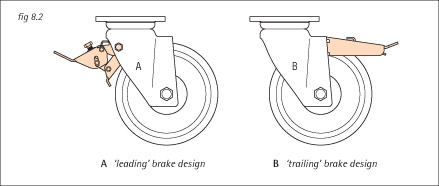

8.2 Total stop brake (fig 8.2)

Also called combined swivel and wheel brake. A foot operated pedal simultaneously

brakes the wheel and locks the swivel head in any position. Total stop brake

mechanisms are fitted in either a ëleadingí or ëtrailingí position.

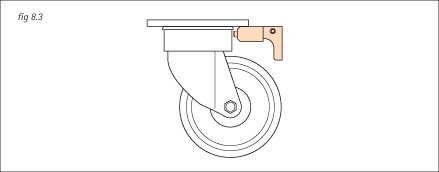

8.3 Directional lock (fig 8.3)

A hand or foot operated lever locks the castor into a fixed position. Some castor types

are available with 2-station (180∞) locks and others with 4-station (90∞) locks. Care

should be taken when using a 4-station lock to ensure that if the lever is left in the ON

position but not engaged during general use, the castor does not subsequently lock at

90 degrees to the direction of travel. This could cause a sudden swerve or damage to

the castor and wheel. Directional locks are supplied welded or in kit form depending

upon castor series.

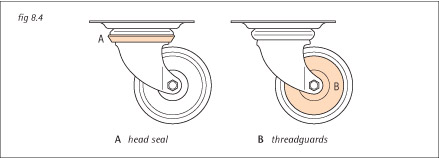

8.4 Swivel seal / threadguards (fig 8.4)

Also called head seal. Usually rubber, where available a head seal can prevent

ingress of dirt and and dust into the castorís swivel head.

Most commonly used in the textile industry, threadguards help to prevent an

accumulation of thread from binding the wheel.

In general, wheels can be sub-divided into two main types:

9.1 Resilient tread wheels

Resilient or soft tread (tyred) wheels, such as rubber or polyurethane, give the ultimate

in quietness and floor protection but introduce a penalty from the point of view of ease

of movement, as the tractive resistance or effort required to move the equipment can

generally be up to three times that of the equivalent sized hard tread wheels.

Polyurethane, however, has the remarkable property of being able to carry loads

approaching those of cast iron, and has a great resistance to tearing and abrasive

wear (many times the life of rubber). It also has a lower tractive resistance than rubber

for the same load and is impervious to mineral oils and greases. For many high load

manual applications soft tread wheels can be ruled out as, although they may be

capable of carrying a high load, the force required to move the equipment would be

excessive.

However, the quiet running and floor protecting properties of a resilient tread make it

particularly suitable for power towing applications.

9.2 Hard tread wheels

In the range of hard tread (or untyred) wheels it is usual to consider the cast iron wheel

as a basic standard as these are generally the strongest and have the longest life.

They are certainly the easiest to push and in many cases will, therefore, be the first

choice for maximum mobility.

They have the disadvantage, however, of being rather noisy and can sometimes

cause excessive floor wear. As an alternative to cast iron, injection moulded or cast

nylon wheels have been developed. Nylon is unaffected by water and its use in the

wet further enhances its self-lubricating properties. The load capacity of nylon

approaches that of cast iron and these wheels also have the additional advantages of

being quieter running, light in weight and unlikely to cause floor damage. They can be

used in the temperature range -40∞c to +80∞c, although it may be necessary to

derate the load capacity by up to 25% for very arduous conditions. For higher

temperature applications, thermoplastic or phenolic resin wheels are also available.

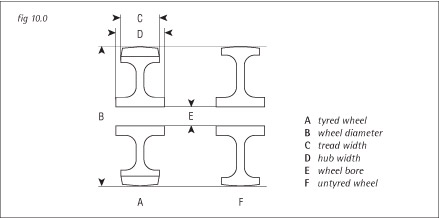

10.0 WHEEL TERMINOLOGY / DEFINITIONS

10.1 Wheel diameter (fig 10.0)

The overall diameter of the wheel (including tyre, if fitted).

10.2 Tread width (fig 10.0)

The overall width of the tread of the wheel at its widest point.

10.3 Hub width (fig 10.0)

The overall width of the wheel at its hub

10.4 Bore (fig 10.0)

The inside diameter of the wheel bore. In the case of a wheel fitted with bearings, the

bore represents the inside diameter of the bearing.

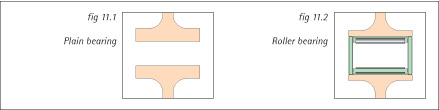

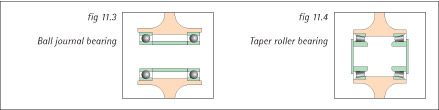

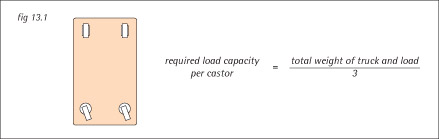

Four main types of wheel bearing are available. Plain bearing (plain bore) wheels are

adequate for many applications where maximum mobility is not essential. Roller

bearings do not increase load capacity but keep rolling resistance to a minimum and

prolong working life. Ball journal and taper roller bearings absorb axial loads and are

essential for power towing applications.

11.1 Plain bearing (fig 11.1)

In the case of cast iron wheels and cast iron centred wheels, frequent lubrication is

essential using the grease nipple or drilled hole in axle bolt, if provided. Nylon and

nylon centred wheels have the axle tube greased on assembly and in good working

conditions will run for a very long time without additional lubrication. There is,

however, a risk of squeaking and excessive axle tube wear in dusty and gritty

conditions.

11.2 Roller bearing (fig 11.2)

Roller bearings are greased on assembly and in light duty applications, under normal

working conditions, should not require replenishment.

Castors designed for heavy duty applications are always provided with a means of

replenishing the lubricant in the roller bearing. In cast iron and cast iron centred

wheels, the roller bearing runs on an outer hardened steel split sleeve which gives

extended life and reduced rolling resistance. In wheels with plastic centres, the split

sleeve is unnecessary and is therefore omitted.

11.3 Ball journal bearing (fig 11.3)

Ball journals are ideal for applications where high radial and moderate axial loads

exist, and give very low rolling resistance. The bearings are shielded to retain grease

and exclude grit and dust. A spacer tube between the bearings is used to support the

inner races which are clamped together end-wise on assembly. No adjustment is

necessary. Ball journals are suitable for both manual and low speed power towing

applications.

11.4 Taper roller bearing (fig 11.4)

Precision tapered roller bearings are suitable for the heaviest applications where high

radial and axle loads are present. Bearing cups and cones are hardened for extended

life and the bearing is adjusted on installation to give optimum service life. Seals are

fitted to retain grease and exclude grit, dirt etc., and grease nipples are provided for

replenishment under arduous working conditions.

Where an application may result in contact with, or exposure to chemicals, each

component of the proposed castor or wheel should be checked for compatibility.

For advice on compatibility, please contact our technical sales department with full

details of chemicals present in your application.

13.0 CASTOR AND WHEEL CONFIGURATIONS

In considering various truck and trolley designs, the correct alignment of fixed and

directional lock castors is essential. In accordance with the relevant ISO standard, top

plate fixing holes have a working clearance of 1mm for all bolts up to 12mm and 2mm

for larger sizes. This accommodates minor positional errors in the manufacture of the

trolley but, unfortunately, also allows the castors to be misaligned to the point where

drag and tyre wear could be excessive. It is therefore necessary to correctly align the

castors before the bolts are finally tightened.

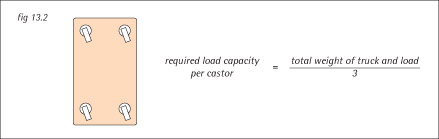

13.1 Two swivel / two fixed castors (fig 13.1)

The most practical configuration for industrial use. This solution provides good load

capacity with good manoeuvrability and ensures accurate steering, even on long

straight runs. The trolley should normally be pushed with the fixed castors leading.

13.2 Four swivel castors (fig 13.2)

This arrangement provides good load capacity with excellent manoeuvrability suitable

for winding runs and where side motion is frequently required. However, trolleys with

this configuration may be difficult to guide on straight runs, particularly with heavy

loads and uneven ground. Not recommended for ramps. If two castors are equipped

with directional locks, this arrangement is then suitable for long straight runs, a very

versatile arrangement.

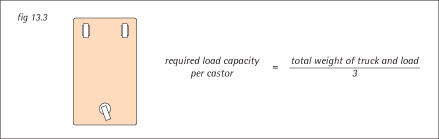

13.3 One swivel / two fixed castors (fig 13.3)

An economical solution for lightly loaded trolleys requiring good manoeuvrability. The

trolley must be fairly small in size and it is essential that the load is evenly distributed

to ensure stability on the unit.

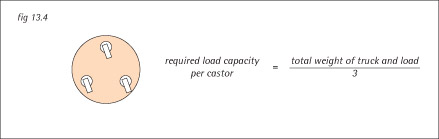

13.4 Three swivel castors (fig 13.4)

This arrangement provides good load capacity with excellent manoeuvrability.

However, equipment with this arrangement will be difficult to guide on straight runs,

particularly over uneven ground. The configuration is ideal for barrel dollies and small

portable machines.

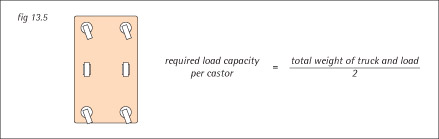

13.5 Four swivel / two fixed castors, centrally pivoting (fig 13.5)

Besides providing a very high load capacity, this arrangement also assures

manoeuvrability and stability. This configuration is best used with longer trolleys

designed to carry heavy loads. The fixed castors could be replaced by axle mounted

wheels and the base of the unit must be of a robust construction. The swivel castors

are mounted in such a way as to pivot the trolley on the central wheels, usually by

packing the fixed castors by approximately 25mm.

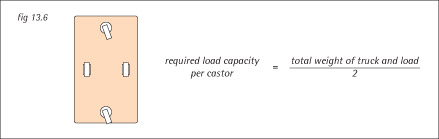

13.6 Two swivel / two fixed castors, centrally pivoting (fig 13.6)

This solution provides good load capacity with excellent manoeuvrability in confined

areas. The fixed castors could be replaced by axle mounted wheels. The swivel

castors are mounted in such a way as to pivot the trolley on the central wheels, usually

by packing the fixed castors by approximately 25mm. The load must be evenly

distributed to ensure stability.

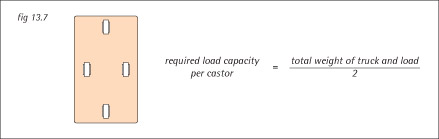

13.7 Four fixed castors, centrally pivoting (fig 13.7)

An economical solution for moderate loads suitable for long, straight runs with

occasional changes in direction. The fixed castors could be replaced by axle mounted

wheels. The swivel castors are mounted in such a way as to pivot the trolley on the

central wheels, usually by packing the central fixed castors by approximately 25mm.

The load must be evenly distributed to ensure stability.

14.0 POWER TOWING APPLICATIONS

Most pressed steel castors are designed specifically for manual propulsion. Due to the

greatly increased stresses exerted on various castor components in power towing,

fabricated castors are recommended. Fabricated castors are designed on the

assumption that power towing will take place in good working conditions and at

speeds of up to 6kph.

Obstructions such as kerbs, gullies and even relatively small steps can exert

enormous impact loads which can destroy a castor. Steps such as lift sills, drain

covers and joints in concrete slabs present a particular problem if they are not

approached squarely. An oblique approach will almost certainly result in the castor

turning at right angles to the obstruction instead of turning in such a way that it can

climb over it. In these circumstances the destruction of the castor is inevitable.

As power towing becomes more common, it is often desirable to tow a number of

trucks or trailers one behind the other. Towing trailers in train though can exacerbate

the problem as only one castor may have to withstand the force generated by the

mass of the whole train including the tractor.

Traditional turntable axles have often been used in this application but, in addition to

being costly, they have two disadvantages:

- If the turntable is at right angles to the axis of the trucks, stability is greatly reduced

- There is a risk of jack-knifing

Castors are, therefore, becoming very popular for power towing and work satisfactorily

provided suitable precautions are taken. It is essential to obviate ëcutting-iní as this

prevents the use of truck trains in narrow gangways.

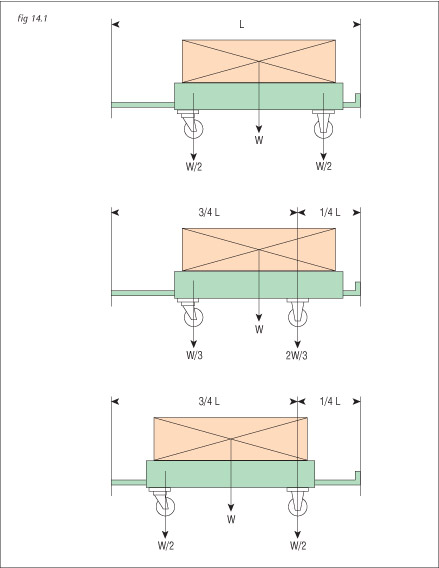

14.1 Castor configurations for power towing (fig14.1)

Experience shows that if trucks are rigidly coupled by means of pin couplings at each

end, they will follow the track most accurately if the distance from the fixed castor

centre-line to the rear coupling pin is 25%-33% of the total length of the truck from front

to rear coupling pins.

This can be achieved by moving the fixed castors forward as shown, but this incurs a

penalty in that it reduces the wheelbase and causes the load to be shared

disproportionately between the swivel and fixed castors.

In order to distribute the load evenly, it is advisable to extend the drawbar at the rear of

the truck as shown in the third arrangement.